Scrap Metal Processing and Testing Services

Processing and Documenting of Metals

At Decco Alloys we processes and document both incoming and outgoing metals.

Our processing and documentation cycle includes:

- Weighing and assigning your material a purchase/lot number using our computerized scrap data system

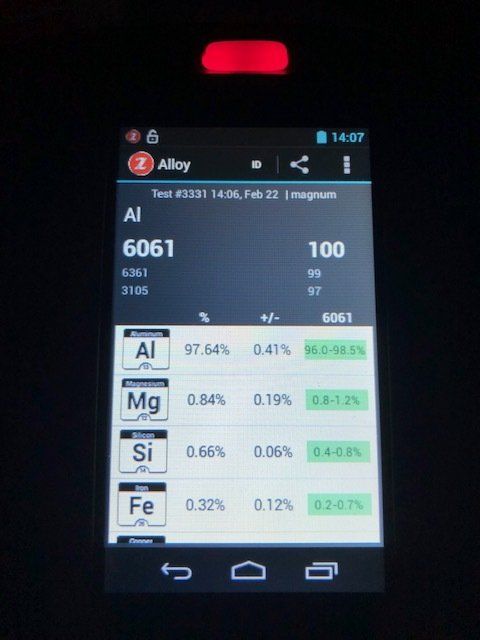

- Metals identification - visual inspection and hand sorting by grade, electronic testing, plus magnetic separation as needed

- Packaging into bales, briquettes, bundles, or other contained forms

- Final inspection prior to loading and shipping to end-user mills and smelters

Superior Metal Testing Services

We have the people, experience, and equipment to sort, identify and grade all incoming materials. Additionally, we can work with you at your facility to segregate mixed and unknown materials for identification.

Our test equipment is state-of-the-art. We have four handheld computer-based X-ray metal identification analyzers, plus two handheld spank test analyzers for aluminum. We can test for many grades of Stainless steel, Aluminium, Nickel, and Cobalt Alloys, Titanium, Copper and Brass, and High-temperature alloys.

All of our equipment is calibrated and tested to meet the critical standards and specifications of the primary mills, foundries and other metal producers we supply.

If you have mixed or unidentified materials and would like assistance with their separation, call us or email us.

Share On: